Sustainability

THE STORY OF CASHMERE

Today, cashmere is a generic name given to the hair of the Hircus Capra goat found in Central and Eastern Asia and like other fibres, its softness is measured by the fineness of the hair –its micronage. However, as its name suggests, the history of cashmere originates in the mountainous region of Kashmir where, in the 15th century, the hair from the mountain goats of Ladakh was used to make shawls for the Persian kings. The Himalayan region still produces this fine fibre but the quality is so delicate that it cannot be used in yarn for knitwear. Rather, it is spun into yarn for careful hand-weaving into the beautiful shawls we know as Shatoosh, Shamina and Pashmina. Although we are straying away from knitwear into the realm of woven cashmere, the story is worth telling…

SHATOOSH

Meaning ‘the King of Fine Wools’ in Persian, the Shatoosh shawl was produced from the hair of the Chiru, a Tibetan Antelope living over 5.000m high up in the Himalayas. The fibre was incredibly fine ( between 9-11micron ) and the resulting shawl so delicate that it could pass through a wedding ring, thus the name “Ring Shawl”.

We refer to the Shatoosh in the past tense as, unfortunately, this priceless shawl is no longer commercially available.

As the secret of Shatoosh become known to the West in the 60s and 70s, the increase in demand led to a dramatic over-hunting of the Chiru. Traditionally the goat’s hair was collected during the summer when it moulted but as demand increased, the animals were killed for their hair. The Chiru’s numbers fell from over a million at the turn of the century to less than 50.000 today and the goat is now classified as an endangered species and commercial trade in the Shatoosh is banned. Those lucky enough to own these incredible shawls treat them as precious heirlooms to pass down the generations…

SHAMINA & PASHMINA

Fortunately for us and the Kashmiri artisans weaving these lovely shawls, another species of goat, the Changhthangi or Pashmina, is still found in the Himalayas and is the source of fine cashmere hair. This hair is still so delicate that it can only be hand-woven into shawls by traditional Kashmiri artisans. The finest hair measuring 13micron is used in the Shamina and the rest into Pashmina shawls.

OUR CASHMERE

The finest cashmere suitable for knitwear yarn from the Hircus Carpa goat comes from the desertic plains of Inner Mongolia. Our suppliers select the very finest fibres available to ensure the very best quality. The softness of the fibre varies with the weather and we use fibre measuring between 15.0 – 15.5 micron for our Premium Cashmere 2/36 quality.

YARN COUNT

The count of a yarn tells you how thin it is. A 36nm count means that 1 kg of yarn will be 36km long. The higher the count, the finer is the yarn and the better the quality as finer yarns require higher quality raw materials to be spun. A 2/36nm count indicates that the yarn consists of 2 yarns of 36nm twisted together – commonly referred to as a 2-PLY yarn.

We use cashmere in 2/36 and 2/28 counts. However, for our Ultrafine Cashmere/Silk and Ultrafine Merinos 180s we use a 3/80nm yarn which is 3-PLY of an exceptionally fine yarn.

GAUGE

Gauges indicate how thick (or fine) your sweater is knitted - it is the number of needles per inch on the knitting machine. A 3gg machine has 3 needles per inch ( a heavy sweater) and a 16gg machine has 16 needles per inch ( a fine sweater). We have machines from 3gg to 18gg so we can knit many different weights of sweaters.

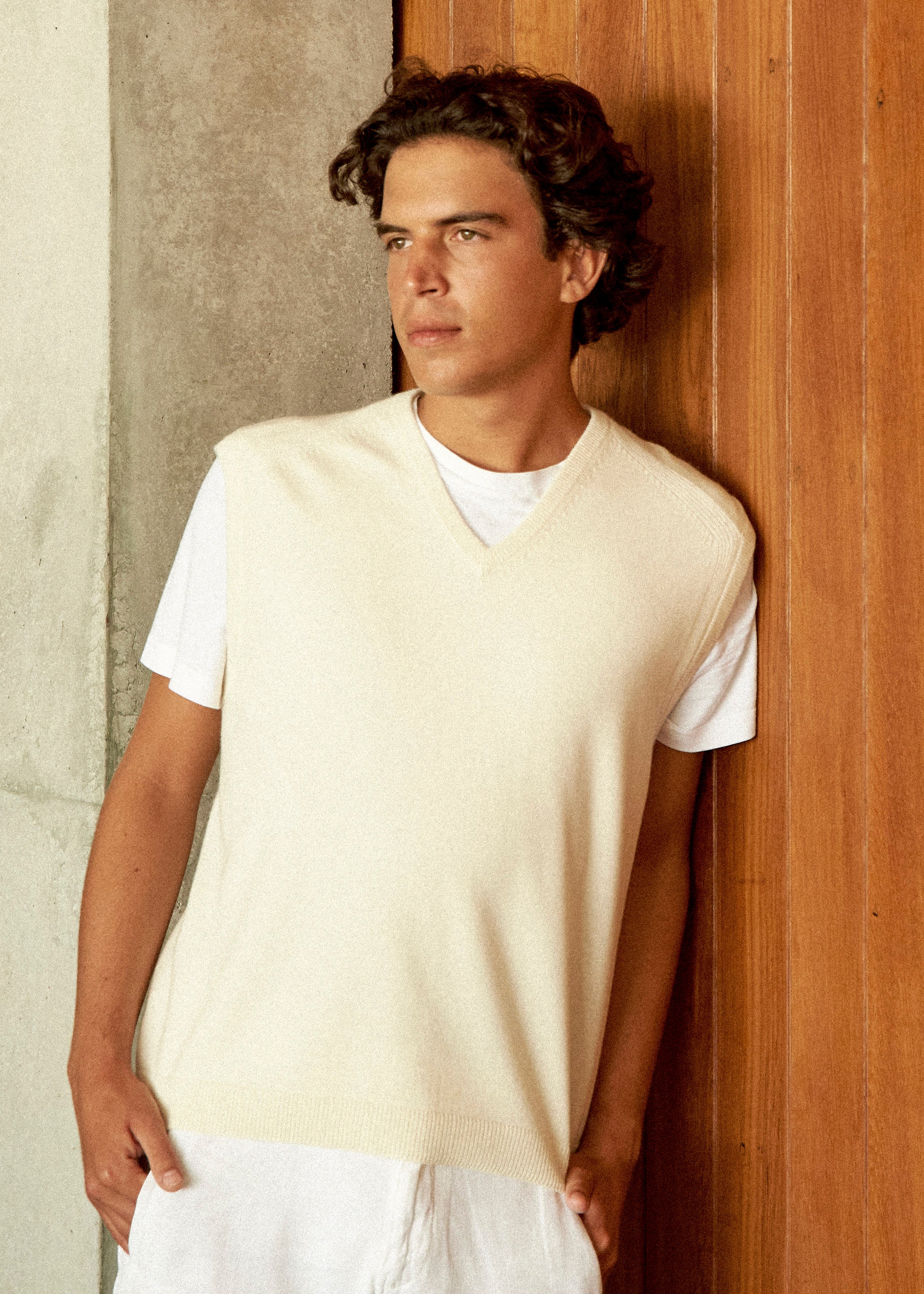

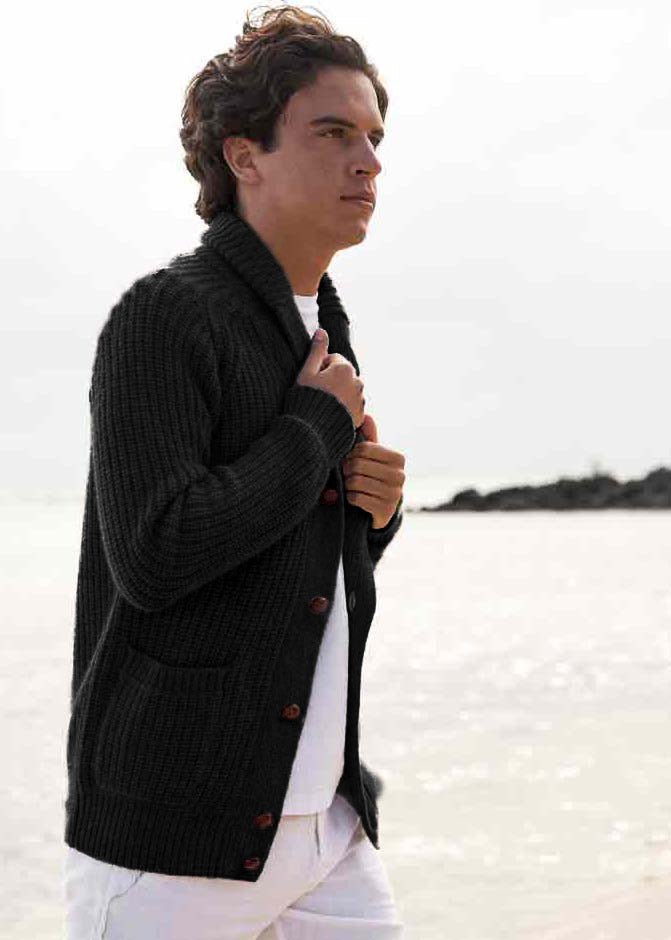

Our Premium Cashmere quality uses a 2/36nm yarn on a 14gg ( 2 PLY). On the other extreme, our chunky cabled CARTER style is knitted on 3gg using 6 yarns of 2/28nm yarn (12 PLY).

We indicate count, ply and gauge on our product descriptions for your interest.

PILLING

Pilling is the formation of little balls of fibre on the surface of your sweater after use. All sweaters made from natural fibres will eventually pill as rubbing raises the fibres and they tangle together forming the balls. It is not, in itself, a sign of poor quality. However, the quality of the raw material used and the density of the knitting will influence the speed and amount of pilling and well-made sweaters will not pill as easily.

Unfortunately, most people associate the softness of a cashmere sweater with quality. This is not the case as it is easy to knit loosely and over-wash a garment to give a soft handle but with reduced longevity and a greater tendency to pill.

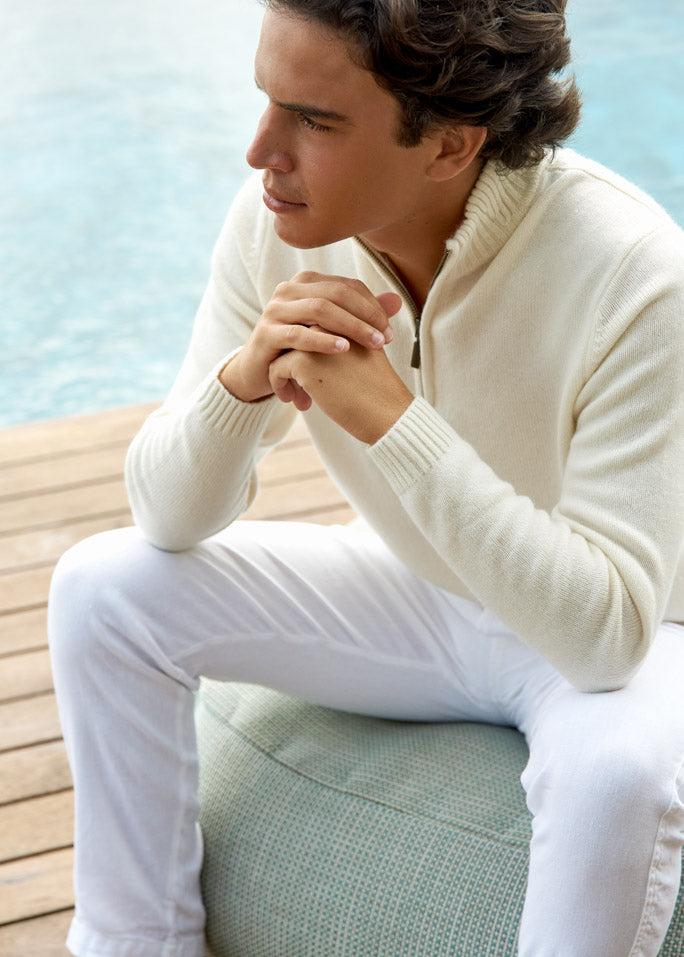

At Atelier Inam, we knit our garments tighter using finer yarns for a fabric which is denser, yet remains light.

And when your garments do show signs of pilling, you can clean them using a cashmere comb.